AnalogEVSE

A basic analog SAE J1772 charge

controller

Last updated: 2023-08-31

|

|

1.

Overview

AnalogEVSE is a simple

SAE J1772 compliant charge controller for EVs. The charge current

can be adjusted from 8A to 64A with a resistor or control voltage.

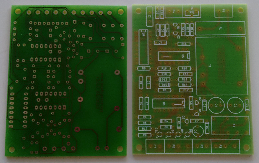

The circuit resides on a single PCB (6.5 cm x 8.4 cm) containing

both the power supply and the pilot signal management. The PCB is

designed to fit into a 4 unit DIN rail enclosure. This makes the

new PCB 30% smaller than the previous version. Additionally, the

frequency calibration is no longer equired. The circuit generates

the pilot signal, measures its voltage levels and operates a relay

which can be used for switching on the high current relay.

The circuit was designed using only common and inexpensive parts.

The main components are 2 LM2901 or LM239 quad comparators (LM339s

with extended temperature range), a CD 4060B, a few transistors

and a handful of passive parts. Everything is analog and there is

no software. Virtually any transistor of the right type (NPN/PNP)

will work. The cost for all components should not exceed 50€. The

PCB is single sided with large tracks and can easily be reproduced

by hobbyists.

The PCB has the following connectors:

- 230V mains

- Relay output

(isolated) 250V/500mA max. 1x make contact (NOC), 1x toggle

- Pilot signal

- Resistor for duty

cycle/charge current selection

- LEDs

- Idle

(white/yellow)

- EV connected

(green)

- Charging (blue)

- Error (red)

Most other analog EVSEs I

know generate the positive part of the pilot signal only. The car

doesn't use the negative signal so charging works with many cars

even if this does not comply with the J1772 standard. However, the

negative half-wave is used for the diode check which is an

essential safety feature. AnalogEVSE has a J1772 compliant

-12V/+12V pilot signal and supports the diode check. Rain water,

dirt or a child's fingers will not be able to turn on the EVSE.

With no EV connected, the Pilot signal is at 12V DC.

If the EV requests ventilation the circuit will close the relay

and enable charging. Since there is no extra relay for a

ventilator the circuit must be used outside only with lead acid

batteries.

The EV will start charging as soon as the connector is plugged in.

There is no extra button for triggering the operation.

The following EVs are known to work with AnalogEVSE:

- Renault ZOE (all

models)

- Hyundai IONIQ

electro

- Mercedes B-Class ED

- BMW i3

- BMW i8

- BMW eDrive

- Tesla Model S, 3 and

X

- Smart ED (old and

new model)

- Toyota Prius Plugin

- Kia Soul EV

- VW Passat GTE

- VW Golf GTE

- VW E-Up!

- VW E-Golf

- Nissan Leaf

- Audi A3 e-tron

- Opel Ampera-e

2. Why Another EVSE?

There are three major

reasons: curiosity, price and simplicity. Commercially available

charge controllers (Phoenix Contact, Wago..) are expensive and

provide a set of features that I don't need. I rarely switch

between charge currents and if I do I want to do it easily

(preferably with a rotary switch). I also want some sort of status

display but it doesn't have to be a text display. I'll never use a

RTC, network, wifi or sophisticated authentication.

So I studied the SAE

J1772 standard and its simplicity is striking. Making a

basic EVSE with analog circuitry is pretty straightforward. I have

found a few analog EVSE circuits on the internet but they are

either too minimalistic/unsafe (BareEVSE),

ignore parts of the standard (only +12V pilot signal) or come without

schematics. So I decided to design a simple analog circuit

that complies with J1772, delivers a +/-12V pilot signal and

supports the diode check for safety reasons.

The main focus of my design is simplicity. The new design uses

less components, has a smaller PCB, lower power consumption and

eliminates the need for frequency calibration by using a quartz

oscillator. The layout is simple and the circuit is tolerant

against assembly mistakes. Debugging is relatively simple and can

be done using basic equipment which makes this design suitable for

use in less developed countries.

3. Circuit States & LEDs

The following table shows

the possible states of the circuit and the corresponding LEDs.

|

LED yellow

Idle

|

LED green

Connected |

LED blue

Charging |

LED red

Error |

No

EV

|

on

|

off |

off |

off |

EV

connected

|

off

|

on

|

off |

off |

EV

charging

|

off |

off |

on

|

off |

EV

requests ventilation

|

off |

off |

on |

off |

Pilot

signal short circuit

|

off |

off |

aus |

on2 |

Diode

test failure

|

off |

off |

aus |

on1,2 |

1 with EV

connected

2

J1772 requires -12V DC. See chapter Limitations.

Note: Using an

RGB LED with a common anode is possible since all LEDs have one

common pin. Use of the Idle LED is optional. However, the other

three LEDs (red, green, blue) must either all be connected or

none at all. Otherwise, they will display wrong status colors.

4. Charge Current

Selection

The charge current can be

set with an external resistor according to the following table.

Intermediate values are supported since the circuit is all analog.

Using a potentiometer is also possible. Please note:

- the

resistance/current ratio is not linear

- the currents listed

below are approximate values which were calculated from

oscilloscope measurements. Due to component tolerances or

temperature drift, the charge current may differ in a real

application.

Rext

|

Charge

current

|

--

|

8A

|

220k

|

10A

|

100k

|

12A

|

56k

|

16A

|

33k

|

20A

|

22k

|

24A

|

15k

|

27A

|

|

Rext

|

Charge

current |

| 10k |

32A |

| 6k8 |

36A |

| 4k7 |

40A |

| 3k3 |

45A |

| 2k7 |

48A |

2k2

|

50A

|

1k5

|

64A

|

|

Alternatively, the charge current can be selected with a control

voltage between 1,5V (64A) and 10V (8A), e.g. by a solar array

controller.

5. Circuit Description

Power supply

The

power supply is a simple +/-12V stabilized circuit using

78L12/79L12. The current requirements are so low that a simple

half-wave rectifier is sufficient.

Note:

the negative supply voltage requires a few mA load in order to

remain stable. Therefore, the onboard power LED is mandatory.

Square wave signal

The

1kHz square wave signal is generated by a quartz oscillator and

filtered into a triangle-ish signal by an RC element. A voltage

comparator is used for transforming it into the square wave. The

comparator's reference voltage defines the duty cycle and can be

adjusted with the external resistor. Using no external resistor

sets the default charge current (8A).

Voltage window

detection

The

square wave signal is split into its negative and positive

half-waves. Both are rectified and filtered to a stable DC

(peak) voltage. The negative part must remain below -8V at all

times (diode check) or the circuit will go to error state.

If the

positive part is below 10V the EV connected LED will light up.

If it is between 7V and 2V the relay will switch on and the

charging LED will light up. For all positive voltages below 2V

(short circuit) the circuit will go to error state. The various

reference voltages are generated by a string of resistors

forming a multi-voltage divider.

Pilot signal

The

pilot signal is generated by two comparators and boosted by a

complementary transistor stage. It is at +12V DC when no EV is

connected.

Relay driver

The relay driver has a

47μF capacitor for debouncing the relay. A bouncing relay can

destroy the EV's charger when using 3-phase charging (e.g.

Renault ZOE).

LED drivers

The LED driver uses

Zener diodes with varying forward voltages so that only one LED

lights up at a time.

6. Emergency Shutdown

An emergency shutdown

is not part of the circuit. However, it can be implemented

easily with a switch that interrupts the 230V power supply. This

will remove power from the circuit and the relay will open.

Please note that an emergency shutdown should only be used in

cases of emergency because the EV prefers to shut down the

charging process gracefully.

Note: the

emergency shutdown circuit my be subject to legal requirements.

7. Access Control

There are several ways

for implementing a simple mechanical access control:

- a lockable emergency

shutdown button that can only be enabled with a key

- a 230V capable key

switch in series with the emergency shutdown button

- a low-voltage key

switch in the pilot signal wire. If the switch is off the

circuit will not sense the EV and the controller will remain

inactive.

8.

Limitations

- The circuit is

designed for charge currents up to around 64A. I have not

investigated higher currents than 32A since my home

installation is limited to 32A.

- EVs requesting

ventilation (lead acid batteries) will be able to charge with

AnalogEVSE but the charging station must be located in a well

ventilated area (preferably outside) as the controller cannot

switch on ventilation. However, this seems to be an academic

issue with modern EVs.

- The pilot signal

carries a square wave in error state (standard says it should

be -12V). However, the relay remains open. Even though this

does not comply with the standard I cannot think of any threat

it would pose. Even if for some reason the car thinks it

should be charging it will be without voltage.

- AnalogEVSE has been

tested with a wide variety of EVs. However, I cannot give any

guarantees that it will work with your EV. That being said, I

see no reason why it shouldn't work with other EVs. I have

been charging my ZOE for more than 3 years using AnalogEVSE

controllers exclusively.

- LM339 are specified

for the temperature range 0 - 70°C. For outdoor applications

it is advisable to use LM2901 or LM239 which have an extended

temperature range of -25 - 85°C. These are included in the

kits.

9. Hints & Modding

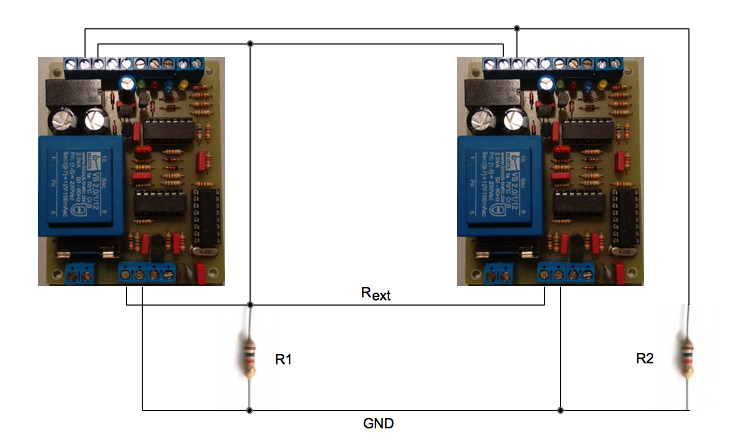

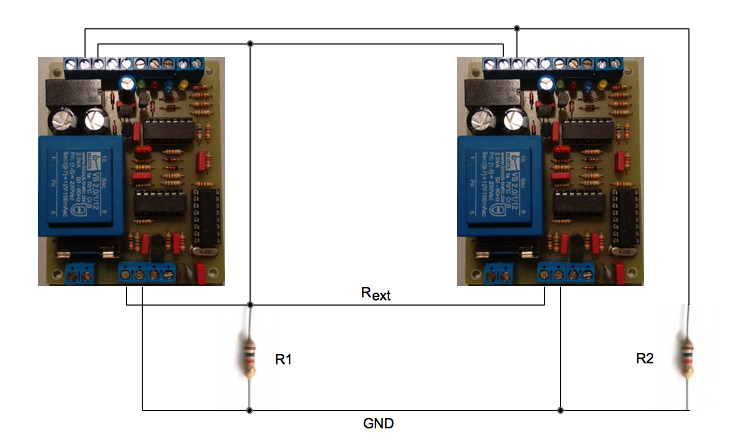

9.1 Load Balancing

If two EVs must be charged

from a single mains supply the generic solution would be to assign

half of the supply power to each EV. This will ensure that the

maximum power of the supply line will never be exceeded even if

both EVs are charging simultaneously. However, this solution will

"waste" half of the supply power if only one EV is connected. This

EV could be charged at twice the power and finish charging much

quicker.

In this scenario, load balancing will dynamically adjust the

available charging power, depending on the number of charging EVs.

A charging station with 2 AnalogEVSE controllers can be

implemented with just two resistors, using the unused second relay

contact. The two resistors (R1 and R2) are connected in parallel

as long as only one EV is charging. If two EVs are charging one of

the resistors (R2) will be disconnected. This raises the

resistance and halves the current.

The values of R1 and R2 are dependent on each other and must be

chosen carefully in order not to overload the mains supply under

all circumstances. First we must select the full throttle current

for a single charging car. We can then look up the corresponding

current selection resistor Rext1

from the table.

Then we determine the resistor Rext2 for half the

current in the same manner. Now we can calculate the two

resistors:

R1 = Rext2 / 2

R2 = 1 / (2 / Rext1 - 1 / R1)

An example:

One EV will charge with 32A, two EVs will charge with 16A each.

Using the table we find:

Rext1 = 10k (for 32A)

Rext2 = 56k (for 16A)

Now we can apply the formula above for calculating R1 and R2. If

there are no matching standard resistors we can either use a

trimpot or a combination of multiple resistors.

R1 = Rext2 / 2 = 56000 / 2 = 28000 closest

standard value 27k

R2 = 1 / (2 / Rext1 - 1 / R1) = 1 / (2 / 10000 -

1 / 27000) = 6136

closest standard value

6.8k

If the calculated value is not readily available it is usually

better to choose a higher value so that the current does not

exceed the limit.

9.3 Additional Hints

- If you intend to set

the controller to a fixed charging current the terminal P2 and

R2 can be replaced with the pot RV2 which can be set to the

desired current. The pot's value can be calculated from using

R2 (10k) and the value of Rext in parallel,

according to the table.

- Make sure you use a

suitable enclosure (IP64 or better) and seal it properly when

mounting the EVSE outdoors. Water and electricity do not go

together well.

- When wiring the box

make sure you use wire colors that comply with national or

company regulations.

10. Construction Manual

10.1 General Hints

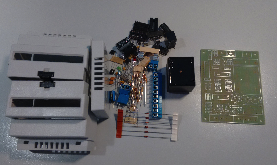

The kit contains all

components that are required for assembling and testing the

AnalogEVSE controller. Populating the PCB requires a certain

amount of soldering experience. Misplaced or misoriented

components will lead to erroneous behavior and may be dangerous.

Please read this manual before starting the assembly.

10.2 Safety

This circuit has 230V

mains voltage and low voltage on a single PCB. When working with

the controller, please be extra careful if the PCB is connected to

the mains.

10.3 Tools

You will need the

following tools:

- a small soldering

iron and thin solder wire

- a wire cutter

- small pliers for

bending wires

- a multimeter

10.4 Preparations

Identify all components

using the BOM and make sure the kit is complete.

Hints for the kit:

- the zener diodes

have pieces of tape

- sometimes LM2901 ICs

are unavailable so I have to substitute them with LM239 or

LM339

10.5 Assembly

10.5.1 General Hints

The basic assembly

procedure goes as follows:

- power supply

assembly and test

- controller assembly

and test

- DIN rail enclosure

installation

All components should be

soldered into place that they touch the surface of the PCB free of

clearance. Transistors and the voltage regulators should be

installed so that their pins are approximately 7mm long.

10.5.2 Assembly and

Test of the Power Supply

Components: P1, P4, P6, F1, T1, D1, D2,

C1, C2, C4, C5, U1, U2

The PCB has pads for different types of transformers. First,

solder the transformer into the matching holes. Check the polarity

of diodes and electrolytic capacitors. The voltage regulators U1

and U2 are different types and must be mounted in the correct

location. It is advisable to slide P4 and P6 together before

mounting them onto the PCB.

When all components have been mounted properly insert the fuse and

connect to 230V~ mains voltage. You

should be able to measure +12V between 0V (P4 Gnd) and pin 3 of

the IC sockets of U3/U5 and

-12V between 0V (P4 Gnd) and pin 12 of these IC sockets. If this is not the case power down

immediately and look for the error.

- Did you bridge

traces with excess solder?

- Did you insert the

fuse and is it still intact?

- Can you measure a

low AC voltage at the transformer's secondary?

- Are the diodes and

electrolytic caps oriented properly?

- Can you measure a DC

voltage at the pins of the electrolytic

caps?

- Are the voltage

regulators oriented properly?

- Did you swap the

voltage regulators?

10.5.3 Assembly and

Startup

Note for owners of

PCB v2.0.4 (Oct. 2021 and later): resistor R20 is not used

and must be bridged with a wire

Mount the diodes D10 and D12 first and use the clipped off wire

ends for the two wire bridges, then mount the IC sockets. Please

make sure you don't forget these wir bridges as it will be nearly

impossible to retrofit them later. Install the remaining terminals

so that their guiding rails interlock. You can also slide them

together before mounting them onto the PCB. You can now install

and solder all remaining components starting with the smallest

pieces. When all components are

assembled insert U3, U4 and U5 into their sockets. You may need

to bend the pins slightly inwards.

Check the PCB carefully and connect it to the main voltage.

Only the yellow idle LED should light up. If this is not the case

switch off immediately and look for the error.

- Did you bridge traces

with excess solder?

- Can you measure the

supply voltage?

- Did you place and

orient the diodes correctly?

- Did you place the

transistors correctly?

- Did you orient the

ICs correctly?

10.5.4 DIN Rail Enclosure

Installation

The recommended (or the

one that comes with the kit) DIN rail enclosure has a little

plastic stabilizer in the center of the front and back access

ports. Unfortunately, this tiny piece of plastic blocks access to

the terminals for LEDs and the pilot signal. However, it can

easily be removed using a sharp knife/wire cutter and a small

file. If done carefully, the procedure will not be visible.

10.5.5 BOM

Download the BOM.

11.

Testing

Once the PCB is

completed the interesting question arises: will it work? In

order to test the functionality of the assembly you need an EV

simulator and an oscilloscope for troubleshooting.

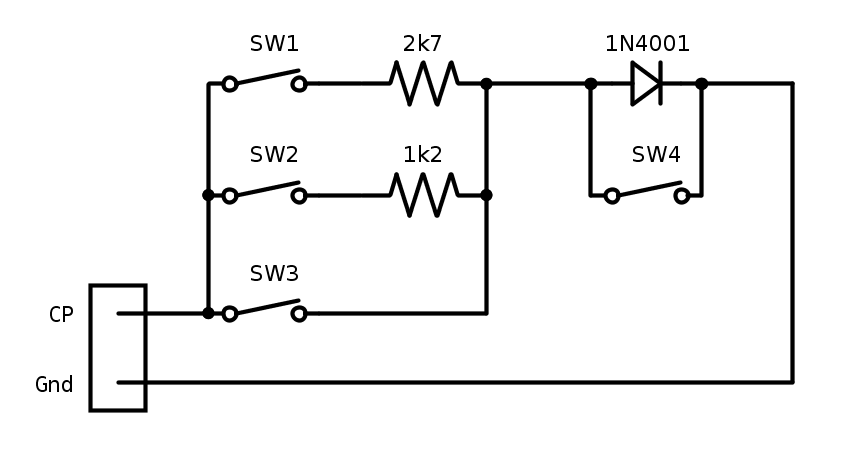

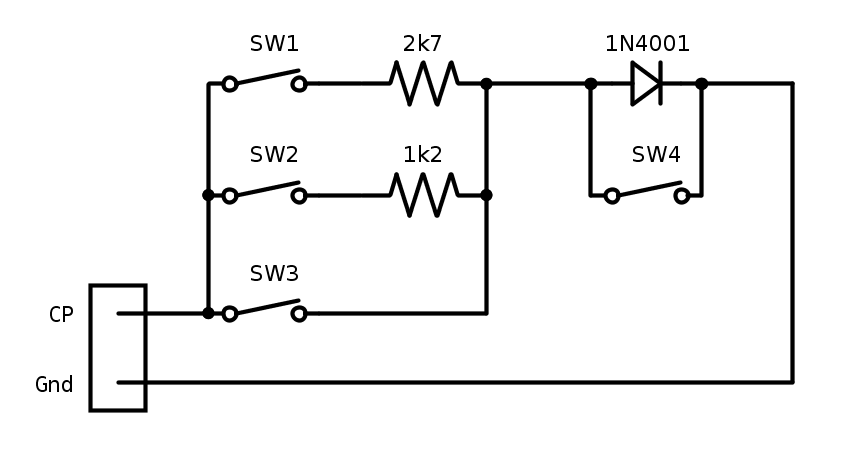

The EV simulator is a

simple circuit which mimics the correct behavior of the EV and

can simulate two distinct errors. The simulator is available as

a kit from OpenEVSE but it is so simple that it can be

built point to point.

|

SW1

|

EV connected

|

SW2

|

EV charging (with SW1 closed)

|

SW3

|

CP short circuit

|

SW4

|

Diode failure

|

When the pilot

signal of the AnalogEVSE PCB is connected to the EV simulator

you can test the following conditions using the on-board LEDs:

SW1

|

SW2

|

SW3

|

SW4

|

State

|

LED

Idle

|

LED

Connected

|

LED

Charge

u. Relais

|

LED

Error

|

off

|

off |

off |

off |

Idle

/ No EV

|

on

|

off |

off |

off |

on

|

off |

off |

off |

EV

connected |

off |

on

|

off |

off |

on

|

on

|

off |

off |

Charging |

off |

off |

on

|

off |

| don't care |

on

|

off |

Pilot

signal short circuit |

off |

off |

off |

on

|

| SW1 and/or SW2 on |

on

|

Diode

error |

off |

off |

off |

on

|

12. Downloads

AnalogEVSE was designed using KiCAD 5.0.1

and has been migrated to KiCAD 7.0.6. KiCAD is a free

EDA software package available for Windows, Linux and Mac OS X.

The KiCAD

project files used to be hosted on Github. However, I

strongly disagree with the latest changes requiring 2FA, so I

abandoned github. The git repository can be downloaded below

instead. Please remember that the latest revisions may not work.

|

| KiCAD Project: |

analogevse-kicad-v2.0.5.zip

Files of the KiCAD project

|

|

Schematics:

|

For

a quick look: Analogevse-v2.0.5-schematic.pdf

Please use the KiCAD files for reference or development as

these will be updated constantly.

|

|

Zip-Archive of Version 1.8:

|

This archive contains the full website as

it was during version 1.8

analogevse-v1.8.zip

If your circuit doesn't seem to match the description on

this page then these files are probably what you need.

|

|

KiCAD:

|

Downloads

KiCAD

Software Download

|

|

Wiring Diagram:

|

Wiring-AnalogEVSE-2.0.X.pdf

Wiring

Diagram for a wallbox using the AnalogEVSE

controller and details about load balancing.

|

|

13. Ordering

You can order the PCB or a full kit from

me using the email address listed below. Postage is included for

shipping within Germany. Please check the table below for

approximate postage and contact me for the exact amount when

placing your order. Note that postage is only required once per

order (not per item).

Delivery time for a kit is approximately

one week since I may have to obtain some components before

shipping. PCBs can be shipped immediately as long as my stash

lasts.

Please note: if you order the PCB

only you will need to find a number of components that match the

footprint on the PCB (e.g. the transformer). Moreover, the PCB

size is tuned exactly to the DIN rail enclosure I use. The kit

includes all components that will match the PCB and the PCB will

fit nicely into the box.

|

|

Price

|

Germany |

EU

|

Worldwide

|

PCB

Professionally manufactured single sided PCB

with solder resist and assembly pressure

|

|

10€

|

no

postage |

+ 4€

postage

|

+ 8€

postage |

Kit

All components required for a complete controller:

PCB, electrical components, transformer, DIN rail enclosure

Without

external resistor Rext

|

|

50€

|

no

postage |

+ 4€

postage |

+ 12€

postage |

12.

Disclaimer

(C) 2015 - 2023

Bernhard Walter

AnalogEVSE is open

source hardware. I designed it for my needs and although I

designed it carefully I cannot guarantee that it is free of

errors. Use it at your own risk.

You are free to build, copy and modify the circuit and its

documentation as long as you include the original copyright

notice and this disclaimer.

Use caution when

working with high voltage. It may kill you.

I am not responsible for the content of linked external web

pages.

Contact: analogevse@web.de

Changelog:

2015-11-19: correction of minor error in PCB layout. Version

changed from 1.3 to 1.4.

2015-11-22: PCB redesign for a standard transformer

2016-09-10: version 1.8

2016-09-20: C11 added

2016-11-04: correction of charge current table

2016-11-07: correction of C10 in BOM

2017-04-19: new PCB layout, new email address

2018-09-25: minor corrections: C1 NP0, LED states for testing

2019-01-01: kits and PCBs no longer available

2019-01-03: update to

Version 2.0.0

2019-03-07: finalized Version 2.0.0

2019-08-21: PCB v2.0.1, BOM as xls

2020-12-21: fixed an error in the construction manual. Thanks

Nick!

2021-10-27: PCB v2.0.4 with R20

2021-11-03: migrated to a new web hoster

2023-08-31: moved away

from github, v2.0.5 fixes the bug that without a car

connected, CP carries the square wave signal instead of 12V DC